OPAL SERİSİ

ODE Opal series waterproofing membranes feature all APP modified bitumen properties. They are manufactured in fiberglass and non-woven polyester felt carrier types. They offer cost effective solutions for all waterproofing details in particular for terrace and foundation applications. They offer extensive usage in climatic conditions of our country.

– They offer cost effective solutions for all waterproofing details.

– They offer extensive usage in the climatic conditions of our country.

– Slated products offer high performance solutions for applications requiring UV resistance.

– Combined with ODE Isıpan DT, they provide high thermal insulation performance solutions for thermal insulated inverted roof.

Benefits:

– Easy application at high temperatures

– High UV resistance

– Long lasting aging process owing to APP additives

– Suitable for vertical application

– Cost effective

Specifications:

| TECHNICAL PROPERTIES | STANDARD | UNIT | OC 200 PRM | OC 300 PRM | OP 300 PRM | OP 400 PRM | OC 400 M PRM | OP 400 M PRM |

| Carrier | – | – | Fiberglass | Fiberglass | Polyester | Polyester | Fiberglass | Polyester |

| Thickness | TS EN 1849-1 | mm | 2±0,02 | 3±0,02 | 3±0,02 | 4±0,02 | 3,5(3,5-3,9) | 3,5(3,5-3,9) |

| Length | TS EN 1848-1 | m | 15±0,03 | 10±0,03 | 10±0,03 | 10±0,03 | 10±0,03 | 10±0,03 |

| Width | TS EN 1848-1 | m | 1±0,02 | 1±0,02 | 1±0,02 | 1±0,02 | 1±0,02 | 1±0,02 |

| Temperature Resistance | TS EN 1110 | °C | ≥110 | ≥110 | ≥110 | ≥110 | ≥110 | ≥110 |

| Cold Bending | TS EN 1109 | °C | ≤ -5 | ≤ -5 | ≤ -5 | ≤ -5 | ≤ -5 | ≤ -5 |

| Water tightness | TS EN 1928 | – | Pass | Pass | Pass | Pass | Pass | Pass |

| Joint Delamination Resistance | EN 12316-1 | N/5cm | ≥ 350 | ≥ 350 | ≥ 400 | ≥ 400 | ≥ 350 | ≥ 400 |

| Joint Delamination Resistance | EN 12317-1 | N/5cm | ≥20 | ≥20 | ≥ 20 | ≥ 20 | ≥20 | ≥ 20 |

| Tensile Strength (Length/Width) | TS EN 12311-1 | N/5cm | ≥300/200 | ≥400/300 | ≥600/400 | ≥600/400 | ≥400/300 | ≥600/400 |

| Elongation at Break (Length/Width) | TS EN 12311-1 | % | ≥2/2 | ≥2/2 | ≥30/30 | ≥30/30 | ≥2/2 | ≥30/30 |

| Tear Resistance (Length/Width) | TS EN 12310-1 | N | ≥70/70 | ≥70/70 | ≥130/130 | ≥130/130 | ≥90/90 | ≥130/130 |

| Reaction to Fire | TS EN 13501-1 | – | E | E | E | E | E | E |

| Roll Dimensions (Length/Width) | – | 15/1 | 10/1 | 10/1 | 10/1 | 10/1 | 10/1 | |

| Number of Rolls per Package | – | 30 | 30 | 30 | 20 | 20 | 20 | |

| Pallet size | cm | 100×120 | 100×120 | 100×120 | 90×115 | 90×115 | 90×115 | |

| Number per pallet | m2/pallet | 450 | 300 | 300 | 200 | 200 | 200 |

Application Areas:

WATERPROOFING OF ROOF TERRACES

Roof terraces which offer usable areas on the roofs and are not visible from the front are divided in two categories depending on the position of the thermal insulation material.

CONVENTIONAL TERRACE ROOF

In conventional terrace roofs the waterproofing insulation is located on the thermal insulation material. A vapor barrier layer is an essential requirement for the flooring to prevent the risk of condensation under the waterproofing membrane. The waterproofing membrane may be exposed to thermal stressand environmental impacts. Although depending on the individual type of the thermal insulation material, problems which might occur on the waterproofing layer may result in the thermal insulation material’s total damage.

- Requires vapor barrier application.

- Application is detailed and difficult.

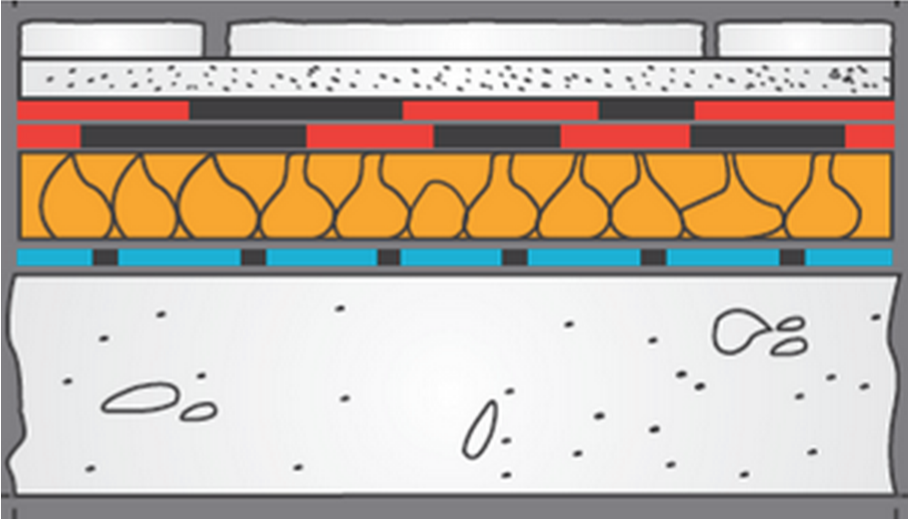

INVERTED TERRACE ROOF

Insulation is applied directly on the flooring surface. No vapor barrier application is required.

The ODE Isıpan DT thermal insulation boards of extruded polystyrene (XPS) are freely placed on waterproofing layer. The waterproofing layer is protected by thermal insulation against environmental impact.

- No vapor barrier application is required.

- The waterproofing layer is protected against potential mechanical impact, thermal stress and UV rays.

- Quick and easy application.

- Low investment costs.

TRAFFICABLE INVERTED TERRACE ROOFS

These terrace roofs are trafficable and suitable for permanent use. ODE Bitumen Emulsion (coat) is applied after cleaning the surface of dust and debris. The first layer of the ODE Membran is completely adhered on the surface after heating with welding torch. Applications on the parapets are performed in such form to remain above the snow level during winter. The second layer of the ODE Membran is heated and completely fastened on the first membrane layer. ODE Isıpan DT extruded polystyrene thermal insulation plates are placed onto the waterproofing layer. Insulation thickness should be set in accordance with the TS 825 standard. Concrete is poured as protective layer and surface coating material is applied.

VENTILATION SHAFT

Double-walled, vapor stabilizing shafts are integrated in the system where necessary.

RAINWATER DRAINAGE

The size of the drainage depends on the surface area. The leaf holder can be used at the top tile level in order to prevent drainage clogging.

PARAPETS

Waterproofing membrane is fastened on the first layer. Waterproofing membranes are elevated vertically and the final waterproofing layer is applied in such form to cover the entire bay.

NON TRAFFICABLE INVERTED TERRACE ROOFS

Except for access for repair, these roofs are mainly non trafficable.

ODE Bitumen Emulsion (lining) is applied after cleansing of the surface from dust and debris. The first layer of the ODE Membran is completely adhered on the surface after heating with welding torch. Applications on the parapets are performed in such form to remain above the snow level during winter. The second layer of the ODE Membran is heated and completely attached on the first membrane layer. ODE Isıpan DT extruded polystyrene thermal insulation plates are placed onto the waterproofing layer. Insulation thickness should be set in accordance with the TS 825 standard. Round pebbles of O 15/35 mm in particle size are laid as protective layer. The height of the pebbled layer varies depending on the thickness of the insulation plate.

BASEBOARD RAINWATER DRAINAGE

Lining is applied to the filter bed. The water insulation tape is welded. Drain pipe is placed on top of this layer. The second membrane is tightly fastened to the pipe.

FOUNDATION WATERPROOFING AS AN ESSENTIAL REQUIREMENT

- Protection of the structural components in contact with soil against heat and moisture

- Convenience of the underground areas

- Prevention of the corrosion of steel concrete reinforcement to preserve resistance

- Extension the building’s longevity

WATER INSULATION PRINCIPLES FOR FOUNDATIONS

- The ground water status must be defined during the highest groundwater levels.

- The foundation and insulation systems are identified through the assessment of the groundwater level.

- Permanent and uninterruptible waterproofing must be present outside the building (TANKING).

- The ground on which waterproofing shall be applied must be firm, dewatered and have a smooth surface.

- The waterproofing membranes must be protected with protective layers after application.

- In order to ensure convenience of the environments, water insulation must be considered jointly with thermal insulation.

DETAILING OF WATER INSULATION FOR FOUNDATIONS

Against the soil humidity

• Water intake by capillarity.

Against pressurized water

• Water causing permanent hydrostatic pressure.

Against unpressurized water

• Flowing rain and potable water.

TANKING

Underground water formation depends on the different permeability characteristics of the soil. For example, coarse sand and gravel are permeable while clay is considered practically impermeable. Tanking is recommended for constant waterproofing in basements resting on an impervious ground.

Underground water is the biggest issue as the building has a direct contact to the impervious soil. The underground water level must be lowered approx. 500 mm below the excavation foundation in order to allow the applications on the excavation site. For this purpose, setting up a pump station maintains the water level throughout the on-site operations. Otherwise, possible sudden elevations may cause damage to the complete applications. Coat the excavation foundation with a smooth lean concrete waterproofing layer. Vertical molds for the foundation concrete are placed. In order to prevent sharp turns, 50mm wide triangular wooden wedges are placed inside the inner corners of the mold. Clean the lean concrete from dust residues and apply ODE Bitumen Emulsion (lining). Overlap approx. 200/300 mm of the first ODE Membran waterproofing layer with the mold and apply completely after heating with a welding torch. Overlap approx. 200/300 mm of the second ODE Membran layer and adhere completely. 3-4 cm thick protective screed should be laid to prevent damage to the waterproofing mat by iron reinforcements of the concrete foundation. Wooden sheet is removed and sharp corners are rounded up in order to protect the mat in vertical axis along the foundation height. The molds should not be removed unless the curtain walls are complete. The curtain walls are cleaned of dust residues and coated with ODE Bitumen Emulsion lining. After removing the molds, 200/300 mm free mats are attached on the foundation pier. Leaving a 200 mm margin, the ODE Membran waterproofing mat is attached at min. 300/500 mm above the ground. Center second layer of ODE Membran waterproofing mat to the bottom mat and attach parallelly after leaving a 200 mm margin. Do not forget the 100 mm joint overlaps. Membrane application is completed after sealing the 200 mm finish overlaps to the foundation pier. Filling is made after placing the ODE Isıpan DT thermal insulation plates as protective.

ODE Granat series water insulation membranes feature all APP modified bitumen properties. They are manufactured in fiberglass and non-woven polyester felt carrier types. They are used with high performance for all waterproofing details and terrace and foundation applications in particular.

– Offer extensive usage in the climatic conditions of our country.

– Provides a high performance thermal insulation solution with ODE Isıpan DT in thermal insulated inverted terrace roofs.

Benefits:

– High performance

– Longer aging process owing to APP additives

– Suitable for vertical application

Specifications:

| TECHNICAL PROPERTIES | STANDARD | UNIT | GC 200 PRM | GC 300 PRM | GP 300 PRM | GP 400 PRM |

| Carrier | – | – | Fiberglass | Fiberglass | Polyester | Polyester |

| Thickness | TS EN 1849-1 | mm | 2(1,8-2,2) | 3(2,8-3,2) | 3(2,8-3,2) | 4(3,8-4,2) |

| Length | TS EN 1848-1 | m | 15±0,03 | 10±0,03 | 10±0,03 | 10±0,03 |

| Width | TS EN 1848-1 | m | 1±0,02 | 1±0,02 | 1±0,02 | 1±0,02 |

| Temperature Resistance | TS EN 1110 | °C | ≥120 | ≥120 | ≥120 | ≥120 |

| Cold Bending | TS EN 1109 | °C | ≤ -10 | ≤ -10 | ≤ -10 | ≤ -10 |

| Water tightness | TS EN 1928 | – | Pass | Pass | Pass | Pass |

| Joint Delamination Resistance | EN 12316-1 | N/5cm | ≥ 350≥ 350 | ≥ 350≥ 350 | ≥ 400≥ 400 | ≥ 400≥ 400 |

| Joint Sliding Strength | EN 12317-1 | N/5cm | ≥20≥20 | ≥20≥20 | ≥ 20 | ≥ 20 |

| Tensile Strength (Length/Width) | TS EN 12311-1 | N/5cm | ≥400/300 | ≥400/300 | ≥800/600 | ≥800/600 |

| Elongation at Break (Length/Width) | TS EN 12311-1 | % | ≥2/2 | ≥2/2 | ≥35/35 | ≥35/35 |

| Tear Resistance (Length/Width) | TS EN 12310-1 | N | ≥70/70 | ≥90/90 | ≥150/150 | ≥150/150 |

| Reaction to Fire | TS EN 13501-1 | – | E | E | E | E |

| Roll Dimensions (Length/Width) | – | 15/1 | 10/1 | 10/1 | 10/1 | |

| Number of Rolls per Package | – | 30 | 30 | 30 | 20 | |

| Pallet Dimensions | cm | 100×120 | 100×120 | 100×120 | 90×115 | |

| Number in Pallets | m2/pallet | 450 | 300 | 300 | 200 |

Application Areas:

WATERPROOFING OF ROOF TERRACES

Roof terraces which offer usable areas on the roofs and are not visible from the front are divided in two categories depending on the position of the thermal insulation material.

CONVENTIONAL TERRACE ROOF

In conventional terrace roofs the waterproofing insulation is located on the thermal insulation material. A vapor barrier layer is an essential requirement for the flooring to prevent the risk of condensation under the waterproofing membrane. The waterproofing membrane may be exposed to thermal stressand environmental impacts. Although depending on the individual type of the thermal insulation material, problems which might occur on the waterproofing layer may result in the thermal insulation material’s total damage.

- Requires vapor barrier application.

- Application is detailed and difficult.

INVERTED TERRACE ROOF

Insulation is applied directly on the flooring surface. No vapor barrier application is required.

The ODE Isıpan DT thermal insulation boards of extruded polystyrene (XPS) are freely placed on waterproofing layer. The waterproofing layer is protected by thermal insulation against environmental impact.

- No vapor barrier application is required.

- The waterproofing layer is protected against potential mechanical impact, thermal stress and UV rays.

- Quick and easy application.

- Low investment costs.

TRAFFICABLE INVERTED TERRACE ROOFS

These terrace roofs are trafficable and suitable for permanent use. ODE Bitumen Emulsion (coat) is applied after cleaning the surface of dust and debris. The first layer of the ODE Membran is completely adhered on the surface after heating with welding torch. Applications on the parapets are performed in such form to remain above the snow level during winter. The second layer of the ODE Membran is heated and completely fastened on the first membrane layer. ODE Isıpan DT extruded polystyrene thermal insulation plates are placed onto the waterproofing layer. Insulation thickness should be set in accordance with the TS 825 standard. Concrete is poured as protective layer and surface coating material is applied.

VENTILATION SHAFT

Double-walled, vapor stabilizing shafts are integrated in the system where necessary.

RAINWATER DRAINAGE

The size of the drainage depends on the surface area. The leaf holder can be used at the top tile level in order to prevent drainage clogging.

PARAPETS

Waterproofing membrane is fastened on the first layer. Waterproofing membranes are elevated vertically and the final waterproofing layer is applied in such form to cover the entire bay.

NON TRAFFICABLE INVERTED TERRACE ROOFS

Except for access for repair, these roofs are mainly non trafficable.

ODE Bitumen Emulsion (lining) is applied after cleansing of the surface from dust and debris. The first layer of the ODE Membran is completely adhered on the surface after heating with welding torch. Applications on the parapets are performed in such form to remain above the snow level during winter. The second layer of the ODE Membran is heated and completely attached on the first membrane layer. ODE Isıpan DT extruded polystyrene thermal insulation plates are placed onto the waterproofing layer. Insulation thickness should be set in accordance with the TS 825 standard. Round pebbles of O 15/35 mm in particle size are laid as protective layer. The height of the pebbled layer varies depending on the thickness of the insulation plate.

BASEBOARD RAINWATER DRAINAGE

Lining is applied to the filter bed. The water insulation tape is welded. Drain pipe is placed on top of this layer. The second membrane is tightly fastened to the pipe.

FOUNDATION WATERPROOFING AS AN ESSENTIAL REQUIREMENT

- Protection of the structural components in contact with soil against heat and moisture

- Convenience of the underground areas

- Prevention of the corrosion of steel concrete reinforcement to preserve resistance

- Extension the building’s longevity

WATER INSULATION PRINCIPLES FOR FOUNDATIONS

- The ground water status must be defined during the highest groundwater levels.

- The foundation and insulation systems are identified through the assessment of the groundwater level.

- Permanent and uninterruptible waterproofing must be present outside the building (TANKING).

- The ground on which waterproofing shall be applied must be firm, dewatered and have a smooth surface.

- The waterproofing membranes must be protected with protective layers after application.

- In order to ensure convenience of the environments, water insulation must be considered jointly with thermal insulation.

DETAILING OF WATER INSULATION FOR FOUNDATIONS

Against the soil humidity

• Water intake by capillarity.

Against pressurized water

• Water causing permanent hydrostatic pressure.

Against unpressurized water

• Flowing rain and potable water.

TANKING

Underground water formation depends on the different permeability characteristics of the soil. For example, coarse sand and gravel are permeable while clay is considered practically impermeable. Tanking is recommended for constant waterproofing in basements resting on an impervious ground.

Underground water is the biggest issue as the building has a direct contact to the impervious soil. The underground water level must be lowered approx. 500 mm below the excavation foundation in order to allow the applications on the excavation site. For this purpose, setting up a pump station maintains the water level throughout the on-site operations. Otherwise, possible sudden elevations may cause damage to the complete applications. Coat the excavation foundation with a smooth lean concrete waterproofing layer. Vertical molds for the foundation concrete are placed. In order to prevent sharp turns, 50mm wide triangular wooden wedges are placed inside the inner corners of the mold. Clean the lean concrete from dust residues and apply ODE Bitumen Emulsion (lining). Overlap approx. 200/300 mm of the first ODE Membran waterproofing layer with the mold and apply completely after heating with a welding torch. Overlap approx. 200/300 mm of the second ODE Membran layer and adhere completely. 3-4 cm thick protective screed should be laid to prevent damage to the waterproofing mat by iron reinforcements of the concrete foundation. Wooden sheet is removed and sharp corners are rounded up in order to protect the mat in vertical axis along the foundation height. The molds should not be removed unless the curtain walls are complete. The curtain walls are cleaned of dust residues and coated with ODE Bitumen Emulsion lining. After removing the molds, 200/300 mm free mats are attached on the foundation pier. Leaving a 200 mm margin, the ODE Membran waterproofing mat is attached at min. 300/500 mm above the ground. Center second layer of ODE Membran waterproofing mat to the bottom mat and attach parallelly after leaving a 200 mm margin. Do not forget the 100 mm joint overlaps. Membrane application is completed after sealing the 200 mm finish overlaps to the foundation pier. Filling is made after placing the ODE Isıpan DT thermal insulation plates as protective.

ODE Rubin series insulation membranes preserve superior properties such as easy SBS modified bitumen application at low temperatures. They are manufactured with fiberglass and non-woven polyester felt carrier.

– They offer high performance solutions for all waterproofing details.

– They offer extensive usage in the climatic conditions of our country.

– Slated products offer high performance solutions for applications requiring UV resistance.

– Combined with ODE Isıpan DT, they provide high insulation performance solutions for thermal insulated inverted roofs.

– Particularly preferred for low temperature applications and steel roofs with high elasticity properties.

Benefits:

– Easy application at low temperatures

– High flexibility

– Easy application in indented / jagged and projects with complex details

Specifications:

|

TECHNICAL PROPERTIES |

STANDARD |

UNIT |

RC 200 PRM |

RC 300 PRM |

RP 300 PRM |

RP 400 PRM |

RP 400 M PRM |

|

Carrier |

– |

– |

Fiberglass |

Fiberglass |

Polyester |

Polyester |

Polyester |

|

Thickness |

TS EN 1849-1 |

mm |

2(1,8-2,2) |

3(2,8-3,2) |

3(2,8-3,2) |

4(3,8-4,2) |

3,5(3,5-3,9) |

|

Length |

TS EN 1848-1 |

m |

15±0,03 |

10±0,03 |

10±0,03 |

10±0,03 |

10±0,03 |

|

Width |

TS EN 1848-1 |

m |

1±0,02 |

1±0,02 |

1±0,02 |

1±0,02 |

1±0,02 |

|

Temperature Resistance |

TS EN 1110 |

°C |

≥100 |

≥100 |

≥100 |

≥100 |

≥100 |

|

Cold Bending |

TS EN 1109 |

°C |

≤ -20 |

≤ -20 |

≤ -20 |

≤ -20 |

≤ -20 |

|

Water tightness |

TS EN 1928 |

– |

Pass |

Pass |

Pass |

Pass |

Pass |

|

Joint Delamination Resistance |

EN 12316-1 |

N/5cm |

≥ 350≥ 350 |

≥ 350≥ 350 |

≥ 400≥ 400 |

≥ 400≥ 400 |

≥ 400≥ 400 |

|

Joint Sliding Strength |

EN 12317-1 |

N/5cm |

≥20≥20 |

≥20≥20 |

≥ 20 |

≥ 20 |

≥ 20 |

|

Tensile Strength (Length/Width) |

TS EN 12311-1 |

N/5cm |

≥400/300 |

≥400/300 |

≥800/600 |

≥800/600 |

≥800/600 |

|

Elongation at Break (Length/Width) |

TS EN 12311-1 |

% |

≥2/2 |

≥2/2 |

≥35/35 |

≥35/35 |

≥35/35 |

|

Tear Resistance (Length/Width) |

TS EN 12310-1 |

N |

≥90/90 |

≥90/90 |

≥150/150 |

≥150/150 |

≥150/150 |

|

Reaction to Fire |

TS EN 13501-1 |

– |

E |

E |

E |

E |

E |

|

Roll Dimensions (Length/Width) |

– |

15/1 |

10/1 |

10/1 |

10/1 |

10/1 |

|

|

Number of Rolls per Package |

– |

30 |

30 |

30 |

20 |

20 |

|

|

Pallet size |

cm |

100×120 |

100×120 |

100×120 |

90×115 |

90×115 |

|

|

Number per pallet |

m2/pallet |

450 |

300 |

300 |

200 |

200 |

Application Areas:

WATERPROOFING OF ROOF TERRACES

Roof terraces which offer usable areas on the roofs and are not visible from the front are divided in two categories depending on the position of the thermal insulation material.

CONVENTIONAL TERRACE ROOF

In conventional terrace roofs the waterproofing insulation is located on the thermal insulation material. A vapor barrier layer is an essential requirement for the flooring to prevent the risk of condensation under the waterproofing membrane. The waterproofing membrane may be exposed to thermal stressand environmental impacts. Although depending on the individual type of the thermal insulation material, problems which might occur on the waterproofing layer may result in the thermal insulation material’s total damage.

- Requires vapor barrier application.

- Application is detailed and difficult.

INVERTED TERRACE ROOF

Insulation is applied directly on the flooring surface. No vapor barrier application is required.

The ODE Isıpan DT thermal insulation boards of extruded polystyrene (XPS) are freely placed on waterproofing layer. The waterproofing layer is protected by thermal insulation against environmental impact.

- No vapor barrier application is required.

- The waterproofing layer is protected against potential mechanical impact, thermal stress and UV rays.

- Quick and easy application.

- Low investment costs.

TRAFFICABLE INVERTED TERRACE ROOFS

These terrace roofs are trafficable and suitable for permanent use. ODE Bitumen Emulsion (coat) is applied after cleaning the surface of dust and debris. The first layer of the ODE Membran is completely adhered on the surface after heating with welding torch. Applications on the parapets are performed in such form to remain above the snow level during winter. The second layer of the ODE Membran is heated and completely fastened on the first membrane layer. ODE Isıpan DT extruded polystyrene thermal insulation plates are placed onto the waterproofing layer. Insulation thickness should be set in accordance with the TS 825 standard. Concrete is poured as protective layer and surface coating material is applied.

VENTILATION SHAFT

Double-walled, vapor stabilizing shafts are integrated in the system where necessary.

RAINWATER DRAINAGE

The size of the drainage depends on the surface area. The leaf holder can be used at the top tile level in order to prevent drainage clogging.

PARAPETS

Waterproofing membrane is fastened on the first layer. Waterproofing membranes are elevated vertically and the final waterproofing layer is applied in such form to cover the entire bay.

NON TRAFFICABLE INVERTED TERRACE ROOFS

Except for access for repair, these roofs are mainly non trafficable.

ODE Bitumen Emulsion (lining) is applied after cleansing of the surface from dust and debris. The first layer of the ODE Membran is completely adhered on the surface after heating with welding torch. Applications on the parapets are performed in such form to remain above the snow level during winter. The second layer of the ODE Membran is heated and completely attached on the first membrane layer. ODE Isıpan DT extruded polystyrene thermal insulation plates are placed onto the waterproofing layer. Insulation thickness should be set in accordance with the TS 825 standard. Round pebbles of O 15/35 mm in particle size are laid as protective layer. The height of the pebbled layer varies depending on the thickness of the insulation plate.

BASEBOARD RAINWATER DRAINAGE

Lining is applied to the filter bed. The water insulation tape is welded. Drain pipe is placed on top of this layer. The second membrane is tightly fastened to the pipe.

FOUNDATION WATERPROOFING AS AN ESSENTIAL REQUIREMENT

- Protection of the structural components in contact with soil against heat and moisture

- Convenience of the underground areas

- Prevention of the corrosion of steel concrete reinforcement to preserve resistance

- Extension the building’s longevity

WATER INSULATION PRINCIPLES FOR FOUNDATIONS

- The ground water status must be defined during the highest groundwater levels.

- The foundation and insulation systems are identified through the assessment of the groundwater level.

- Permanent and uninterruptible waterproofing must be present outside the building (TANKING).

- The ground on which waterproofing shall be applied must be firm, dewatered and have a smooth surface.

- The waterproofing membranes must be protected with protective layers after application.

- In order to ensure convenience of the environments, water insulation must be considered jointly with thermal insulation.

DETAILING OF WATER INSULATION FOR FOUNDATIONS

Against the soil humidity

• Water intake by capillarity.

Against pressurized water

• Water causing permanent hydrostatic pressure.

Against unpressurized water

• Flowing rain and potable water.

TANKING

Underground water formation depends on the different permeability characteristics of the soil. For example, coarse sand and gravel are permeable while clay is considered practically impermeable. Tanking is recommended for constant waterproofing in basements resting on an impervious ground.

Underground water is the biggest issue as the building has a direct contact to the impervious soil. The underground water level must be lowered approx. 500 mm below the excavation foundation in order to allow the applications on the excavation site. For this purpose, setting up a pump station maintains the water level throughout the on-site operations. Otherwise, possible sudden elevations may cause damage to the complete applications. Coat the excavation foundation with a smooth lean concrete waterproofing layer. Vertical molds for the foundation concrete are placed. In order to prevent sharp turns, 50mm wide triangular wooden wedges are placed inside the inner corners of the mold. Clean the lean concrete from dust residues and apply ODE Bitumen Emulsion (lining). Overlap approx. 200/300 mm of the first ODE Membran waterproofing layer with the mold and apply completely after heating with a welding torch. Overlap approx. 200/300 mm of the second ODE Membran layer and adhere completely. 3-4 cm thick protective screed should be laid to prevent damage to the waterproofing mat by iron reinforcements of the concrete foundation. Wooden sheet is removed and sharp corners are rounded up in order to protect the mat in vertical axis along the foundation height. The molds should not be removed unless the curtain walls are complete. The curtain walls are cleaned of dust residues and coated with ODE Bitumen Emulsion lining. After removing the molds, 200/300 mm free mats are attached on the foundation pier. Leaving a 200 mm margin, the ODE Membran waterproofing mat is attached at min. 300/500 mm above the ground. Center second layer of ODE Membran waterproofing mat to the bottom mat and attach parallelly after leaving a 200 mm margin. Do not forget the 100 mm joint overlaps. Membrane application is completed after sealing the 200 mm finish overlaps to the foundation pier. Filling is made after placing the ODE Isıpan DT thermal insulation plates as protective.